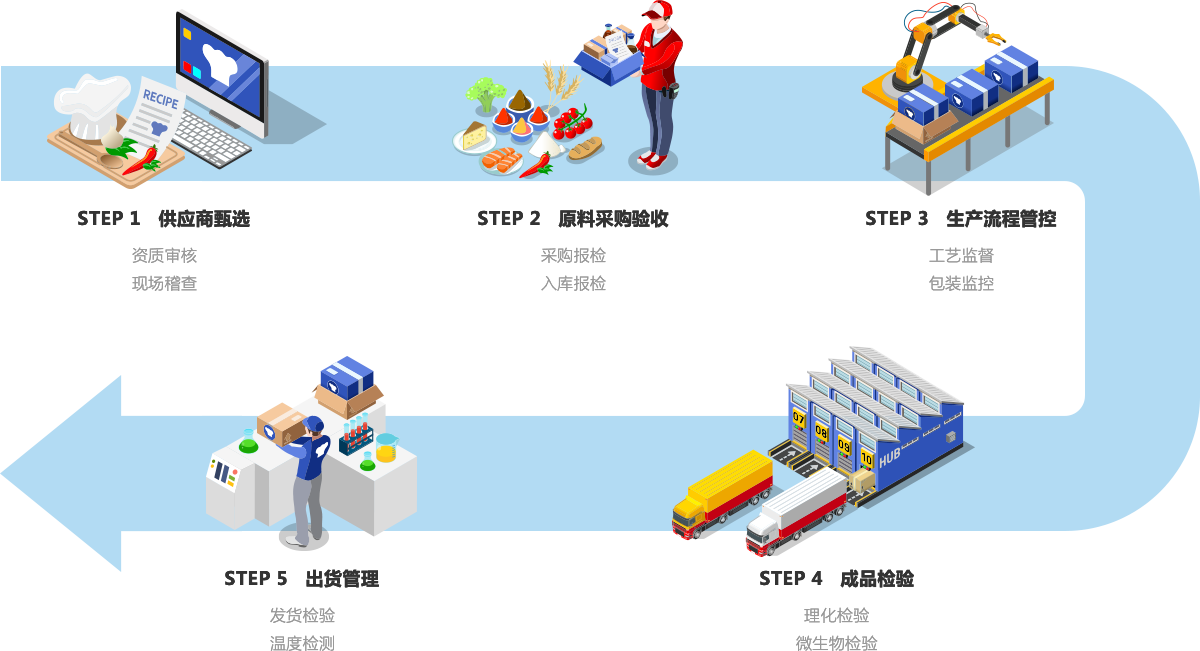

From the careful selection of suppliers, to the procurement and acceptance of raw materials, the control of the production process, the inspection of finished products, and finally to shipping management, every PFI Foods staff member strictly enforces quality control. Each step in the supply chain is closely monitored to ensure that only the highest - quality products reach the market, reflecting the company's unwavering commitment to food safety and quality.

1. In - production Quality Assurance

During the production process, each product is subject to real - time inspection by an integrated metal detection and weighing machine. This advanced equipment automatically identifies and removes any substandard items. By doing so, it guarantees that all products are free from foreign objects and meet the established weight criteria. Simultaneously, detailed production information and batch - specific data are automatically collated into reports. These reports play a crucial role in facilitating in - depth production data analysis, enabling PFI Foods to continuously optimize its production processes and maintain high - quality standards.

2. Factory Hygiene Management

In the realm of factory environmental hygiene control, PFI Foods employs state - of - the - art tools. "Ozone generators" are set to operate at regular intervals, effectively sterilizing the production area. Additionally, "ATP detectors" are used to test the colony counts on personnel and equipment. This two - pronged approach comprehensively ensures that the workshop maintains a sterile production environment, safeguarding the integrity and safety of the food products being manufactured.